Uncategorized

How Hawaiian Shirts Are Made: A Complete Guide to the Craftsmanship Behind Aloha Shirts

Have you ever wondered about how Hawaiian shirts are made, tropical Hawaiian shirts that instantly transport you to paradise? The creation of an authentic Hawaiian shirt is a fascinating blend of artistry, craftsmanship, and cultural heritage that goes far beyond simply printing a tropical pattern on fabric.

From the initial design concept to the final stitching, each aloha shirt undergoes a meticulous manufacturing process that honors both traditional techniques and modern innovation. Understanding how these iconic garments are made reveals the dedication and skill required to produce the high-quality shirts that have become synonymous with relaxation and tropical style.

The History and Cultural Significance of Hawaiian Shirt Manufacturing

The Hawaiian shirt manufacturing process has deep roots in the islands’ multicultural history. Originally created in the 1930s by local tailors who combined Japanese kimono-making techniques with Western shirt construction, these garments represent a unique fusion of cultures and craftsmanship traditions.

Early Hawaiian shirt makers were primarily Japanese immigrants who brought their textile expertise to the islands. They began creating shirts using leftover kimono fabrics, incorporating traditional Hawaiian motifs like hibiscus flowers, palm trees, and ocean waves into their designs. This cultural exchange laid the foundation for what would become a globally recognized symbol of Hawaiian culture.

The evolution of manufacturing techniques has preserved these traditional elements while incorporating modern efficiency. Today’s aloha shirt production maintains the quality standards established by these early craftsmen, ensuring each shirt meets the authentic Hawaiian shirt specifications that have made them beloved worldwide.

Design Development and Pattern Creation

The journey of every Hawaiian shirt begins with the creative design process. Hawaiian shirt designers draw inspiration from the natural beauty of the islands, incorporating elements like tropical flowers, marine life, volcanic landscapes, and traditional Polynesian patterns into their artwork.

Professional designers spend considerable time researching authentic Hawaiian motifs and color palettes. They study traditional tapa cloth patterns, native flora and fauna, and cultural symbols to ensure their designs respect Hawaiian heritage while appealing to modern consumers. This research phase is crucial for maintaining the authenticity that distinguishes genuine Hawaiian shirts from generic tropical prints.

Once the initial concept is developed, designers create detailed digital artwork using specialized software. The pattern repeat process is particularly important, as Hawaiian shirt patterns must seamlessly connect when printed on fabric. This requires precise mathematical calculations to ensure the design flows naturally across seams and maintains visual harmony throughout the garment.

How Hawaiian Shirts Are Made? Fabric Selection and Preparation

The choice of fabric is fundamental to creating an authentic Hawaiian shirt. Traditional Hawaiian shirt fabrics include cotton, rayon, and silk, each offering unique characteristics that affect the final product’s comfort, durability, and appearance.

Cotton remains the most popular choice for its breathability and durability. High-quality cotton fabrics used in Hawaiian shirt production typically have a thread count between 200-300, providing the perfect balance of softness and structure. Rayon fabrics are prized for their silk-like feel and excellent drape, making them ideal for creating the flowing, relaxed silhouette that defines Hawaiian shirts.

Before printing, fabrics undergo a thorough preparation process called pre-treatment. This involves washing to remove any sizing or impurities, followed by chemical treatments that ensure optimal dye absorption. The fabric is then dried and pressed to create a smooth, uniform surface ready for the printing process.

The Printing Process: Bringing Designs to Life

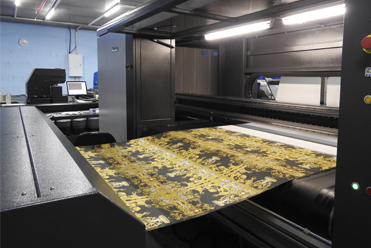

Modern Hawaiian shirt manufacturing employs several fabric printing techniques, each offering distinct advantages for different design requirements. The most common methods include screen printing, digital printing, and rotary printing, with each technique carefully selected based on the complexity of the design and production volume.

Screen printing remains the gold standard for high-volume production of Hawaiian shirts. This process involves creating individual screens for each color in the design, then applying ink through fine mesh screens onto the fabric. Screen printing produces vibrant, long-lasting colors and is particularly effective for designs with solid color areas and bold patterns.

For more complex designs with multiple colors and gradients, digital fabric printing offers superior flexibility. This technology allows for intricate detail reproduction and unlimited color combinations, making it ideal for photorealistic tropical scenes and detailed floral patterns that characterize premium Hawaiian shirts.

“The printing process is where the magic happens. A skilled printer can make the difference between a mediocre tropical shirt and an authentic Hawaiian masterpiece that captures the true spirit of aloha.” – Master Printer, Honolulu Shirt Company

Quality control during the printing phase is critical. Each batch of printed fabric undergoes thorough inspection to ensure color consistency, pattern alignment, and print quality. Any imperfections are immediately addressed to maintain the high standards expected of authentic Hawaiian shirts.

Cutting and Pattern Layout

Once the fabric is printed and quality-approved, the cutting process begins. This stage requires exceptional skill and precision, as proper pattern layout directly affects the final appearance of the Hawaiian shirt. Professional pattern makers must carefully consider how the printed design will align across different parts of the garment.

The pattern matching technique is particularly crucial for Hawaiian shirts. Skilled cutters ensure that tropical motifs flow seamlessly from the front panels to the back, and that pocket placements complement rather than interrupt the overall design. This attention to detail distinguishes high-quality Hawaiian shirts from mass-produced alternatives.

Modern cutting operations use computer-controlled cutting machines for precision and efficiency. However, many premium Hawaiian shirt manufacturers still employ experienced hand-cutters who can make real-time adjustments to optimize pattern placement and minimize fabric waste while maintaining design integrity.

Component Preparation

After cutting, all shirt components are organized and prepared for assembly. This includes the front and back panels, sleeves, collar pieces, cuffs, and pocket components. Each piece is carefully inspected and sorted to ensure proper matching and quality before moving to the sewing department.

Interfacing is applied to collar and cuff pieces to provide structure and durability. The type and weight of interfacing used can significantly impact the final appearance and feel of the Hawaiian shirt, with lighter weights preferred for the relaxed, casual aesthetic that defines authentic aloha wear.

The Sewing and Assembly Process

The Hawaiian shirt assembly process requires skilled seamstresses and specialized sewing techniques. Unlike standard shirt construction, Hawaiian shirts often feature unique design elements such as matching pocket placement, continuous pattern flow, and specialized seaming techniques that maintain the garment’s relaxed fit.

The assembly typically begins with joining the shoulder seams, followed by attaching the sleeves. Precision sewing techniques ensure that seams are strong yet flexible, accommodating the relaxed movement expected from Hawaiian shirts. French seams or flat-fell seams are commonly used for their durability and clean appearance.

Collar construction is particularly important for Hawaiian shirts. The collar must maintain its shape while remaining soft and comfortable against the neck. This requires careful attention to interfacing placement, seam allowances, and pressing techniques throughout the construction process.

Pocket and Button Details

Hawaiian shirt pockets are typically positioned to complement the overall design rather than interrupt it. Pocket placement requires careful consideration of the printed pattern, often positioning pockets to highlight specific design elements like tropical flowers or scenic motifs.

Button selection and placement also contribute to the shirt’s authentic appearance. Traditional Hawaiian shirts feature buttons made from natural materials like coconut shell, mother-of-pearl, or wood. These buttons are not only functional but serve as decorative elements that enhance the tropical aesthetic.

Quality Control and Finishing Touches

Before any Hawaiian shirt leaves the manufacturing facility, it undergoes rigorous quality control inspection. This multi-step process examines every aspect of the garment, from seam strength and button attachment to pattern alignment and overall construction quality.

Inspectors check for common issues such as uneven stitching, misaligned patterns, color variations, and fabric defects. Any shirts that fail to meet quality standards are either repaired or rejected, ensuring that only the finest products reach consumers.

- Seam integrity testing – Ensuring all seams can withstand normal wear and washing

- Colorfastness verification – Confirming that colors won’t fade or bleed during washing

- Pattern alignment assessment – Verifying proper matching across seams and pockets

- Button and hardware inspection – Checking secure attachment and functionality

- Overall fit and appearance review – Ensuring the shirt meets size specifications and aesthetic standards

Environmental Considerations in Hawaiian Shirt Manufacturing

Modern Hawaiian shirt manufacturers are increasingly adopting sustainable production practices to minimize their environmental impact. This includes using eco-friendly dyes, reducing water consumption in the printing process, and implementing waste reduction strategies throughout production.

Many manufacturers now source organic cotton and other sustainable fabrics for their Hawaiian shirts. These materials not only reduce environmental impact but often provide superior comfort and durability compared to conventional alternatives.

Water treatment systems are implemented to ensure that printing and dyeing processes don’t harm local water sources. Advanced filtration and recycling systems allow manufacturers to reuse water while safely processing any chemicals used in production.

The Role of Technology in Modern Production

Manufacturing technology has revolutionized Hawaiian shirt production while maintaining traditional quality standards. Computer-aided design (CAD) systems allow designers to create more complex and detailed patterns while reducing development time.

Automated cutting systems ensure precision and reduce waste, while advanced sewing machines equipped with computer controls can handle complex seaming operations with unprecedented accuracy. However, many premium manufacturers still rely on skilled craftspeople for critical operations that require human judgment and expertise.

“Technology enhances our capabilities, but it can never replace the human touch that gives each Hawaiian shirt its unique character and authenticity.” – Production Manager, Maui Shirt Works

Customization and Made-to-Order Options

Many Hawaiian shirt manufacturers now offer customization services that allow customers to create personalized garments. This might include custom sizing, unique color combinations, or even completely original designs based on customer specifications.

The made-to-order process typically involves detailed consultations to understand customer preferences, followed by pattern creation and small-batch production. While this approach requires more time and resources, it allows for exceptional personalization and exclusivity.

Digital printing technology has made small-run customization more economically viable, enabling manufacturers to offer personalized Hawaiian shirts without the traditional minimum order quantities required for screen printing.

Care and Maintenance of Hawaiian Shirts

Understanding the manufacturing process helps consumers better appreciate how to care for their Hawaiian shirts. Proper care and maintenance can significantly extend the life of these garments while preserving their vibrant colors and comfortable feel.

Most high-quality Hawaiian shirts are designed to be machine washable, but following specific care instructions is essential. Cold water washing helps preserve colors, while gentle cycles protect the fabric structure and prevent premature wear.

- Wash in cold water with like colors to prevent fading and bleeding

- Use mild detergent without bleach or harsh chemicals

- Air dry when possible to prevent heat damage and shrinkage

- Iron on medium heat if needed, using the reverse side to protect prints

- Store properly on hangers to maintain shape and prevent wrinkles

The Future of Hawaiian Shirt Manufacturing

The future of Hawaiian shirt production looks toward even greater sustainability and customization capabilities. Emerging technologies like 3D printing and smart textiles may eventually influence how these garments are designed and manufactured.

Sustainability initiatives continue to drive innovation in fabric sourcing, production processes, and waste reduction. Many manufacturers are exploring circular economy principles, designing shirts that can be fully recycled at the end of their useful life.

Consumer demand for authentic, high-quality Hawaiian shirts continues to grow, encouraging manufacturers to maintain traditional craftsmanship standards while embracing beneficial technological advances. This balance ensures that future generations will continue to enjoy these iconic garments.

Frequently Asked Questions About Hawaiian Shirt Manufacturing

How long does it take to make a Hawaiian shirt?

The complete process from design to finished product typically takes 2-4 weeks for standard production runs. Custom or made-to-order shirts may require 4-6 weeks depending on complexity and customization requirements.

What makes an authentic Hawaiian shirt different from other tropical shirts?

Authentic Hawaiian shirts feature specific design elements, construction techniques, and quality standards that distinguish them from generic tropical prints. This includes proper pattern matching, quality fabric selection, and traditional motifs that respect Hawaiian cultural heritage.

Can Hawaiian shirts be made from recycled materials?

Yes, many modern manufacturers are incorporating recycled fibers and sustainable materials into their Hawaiian shirt production. This includes recycled polyester blends and organic cotton alternatives that maintain comfort while reducing environmental impact.

Why are authentic Hawaiian shirts more expensive than mass-produced alternatives?

The higher cost reflects the quality materials, skilled craftsmanship, and attention to detail required for authentic production. Premium Hawaiian shirts undergo more rigorous quality control and often feature superior construction techniques that ensure longevity and comfort.

Conclusion: Appreciating the Craft Behind Every Hawaiian Shirt

The manufacturing process of Hawaiian shirts reveals a fascinating blend of traditional craftsmanship and modern technology. From the initial design concept to the final quality inspection, each step requires skill, attention to detail, and respect for the cultural heritage these garments represent.

Understanding how Hawaiian shirts are made helps consumers make informed decisions when selecting these iconic garments. Whether choosing a traditional aloha shirt for special occasions or a casual Hawaiian shirt for everyday wear, appreciation for the manufacturing process enhances the overall experience of owning these unique pieces.

The dedication of designers, printers, cutters, and seamstresses ensures that each Hawaiian shirt maintains the quality and authenticity that has made them beloved worldwide. As manufacturing continues to evolve, the core principles of quality, authenticity, and cultural respect remain at the heart of true Hawaiian shirt production.

When you slip on your next Hawaiian shirt, take a moment to appreciate the craftsmanship and care that went into creating this piece of wearable art. Each shirt represents hours of skilled work and generations of traditional knowledge, making it much more than just a garment it’s a celebration of Hawaiian culture and exceptional craftsmanship.

For those seeking authentic, high-quality Hawaiian shirts that honor this rich manufacturing tradition, AllHawaiianShirts.com offers an extensive collection crafted with the attention to detail and cultural respect that defines genuine aloha wear.